From 2017 to now, Repskiller factory is committed to making rep sneakers with Original materials

▪ Factory equipment ▪

We use the same functional equipment as the original to make and process our products

(1) Vulcanization processing box

【Applicable to VANS、CONVERSE and BLAZER models】

(2) Sewing Equipments –

【Sourcing from Japan】

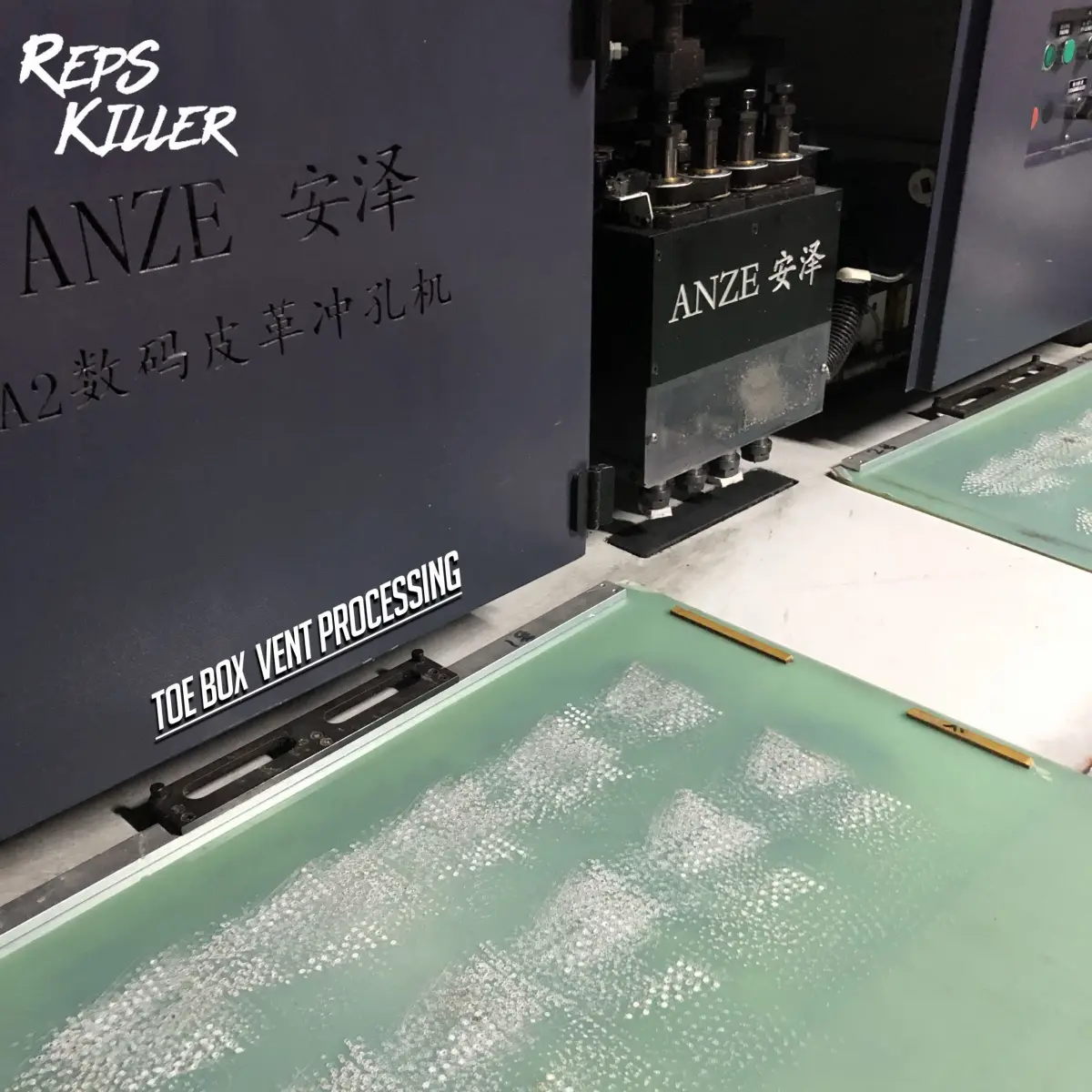

(3) ToeBox vent processing machine –

【Applicable to AIR JORDAN and AIR FORCE models】

(4) Automatic Sewing Machine –

【We need to import the original data into the computer】

(5) Heel shaping machine –

【After the upper is completed, we need to fully shape the heel】

(6) High temperature oven – Maximum temperature up to 165°C

According to the principle of heat expansion and cold contraction, the upper is completely fitted to theshoe last

(7) Special Glass Knife –

【Use this glass cutter to cut the leather, making sure the edges are cleaned up】

(8) Air Conditioner –

According to the principle of heat expansion and cold contraction, the upper is completely fitted to theshoe last

(9) YEEZY350 Series shoes sole mold –

(10) Automatic embroidery –

【We need to import the original data into the computer】

It is mainly used to work on embroidered details, such as the heel of the TSxAJ1.

HAPPY CLIENTS